The increasing labor cost in the USA and other leading economies has forced various companies to move their manufacturing operations off-shore, mainly to China, India, Taiwan, and Vietnam

Over the years, this practice has revealed its shortcomings: the supply chain cost has increased while efficiency has dropped.

To make things worse, these off-shore logistic operations became one of the biggest sources of CO2 emissions.

Finally, there is a problem of less-regulated waste disposal and labor practices in many off-shore economies.

However, new generations of consumers are more environmentally aware than their parents — they intentionally choose companies and brands with low carbon footprint, sustainable supply chain, and fair labor practices.

This is why many companies are trying to achieve sustainable manufacturing by introducing innovative technologies, such as robotics, AI, IoT, blockchain technology, and other Industry 4.0 strategies.

These innovations have already proven their potential in reducing wastage and energy loss, saving time, and increasing productivity.

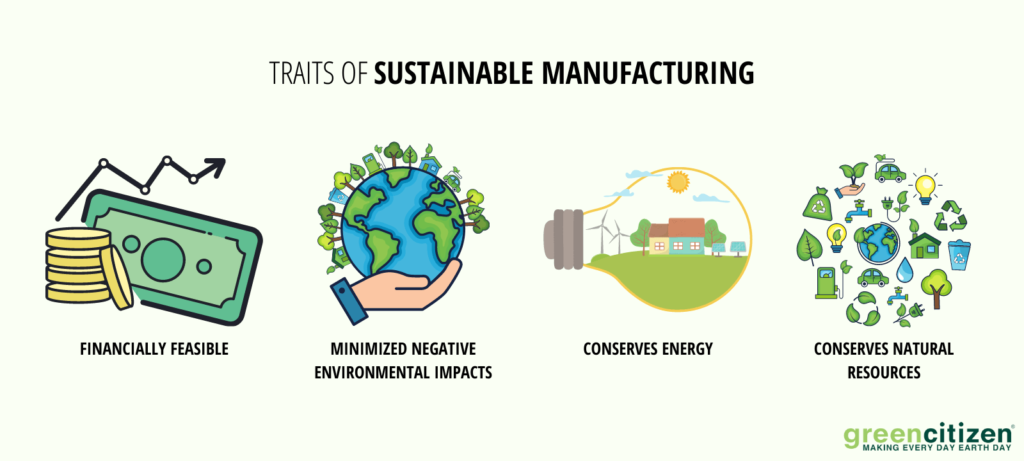

What is Sustainable Manufacturing?

Sustainable manufacturing is the creation of industrial products through money-saving processes that minimize negative environmental impacts, while at the same time conserving energy and natural resources.

Sustainable manufacturing also increases the safety of employees, the community, and products.

The United Nations underline that sustainable manufacturing needs to meet “the needs of the present without compromising the ability of future generations to meet their own needs.”

This means we must avoid wasteful practices for the sake of future generations. If we over-consume resources, our children will inherit a world that wouldn’t be able to support their needs.

However, to achieve this, sustainable manufacturing also needs to be based on a real-world economy.

In other words, sustainable strategies need to be financially feasible to work.

Logically, if a business isn’t profitable, it will have to close its doors at one point.

And here’s the interesting part:

Innovative technologies such as robotics, AI, and the Internet of Things can actually make sustainable practices and profitable practices work together.

Why Should Companies Become Sustainable?

With this in mind, more and more companies are making sustainability an essential part of their strategy and a tool to increase both growth and global presence.

The good news is that this sustainability trend has reached far beyond the small niche of businesses that are traditionally “green”.

Today, companies across diverse industry sectors are making efforts to make their manufacturing more sustainable.

There are many benefits to sustainable manufacturing.

It can help the companies in many ways:

Boost Operation Efficiency by Cutting Costs and Waste

According to McKinsey, a resilient sustainability strategy can reduce costs and affect operating profits by almost 60%. It also saves water and energy.

Running a sustainable production can also build relations with the government bodies and the local community, in the form of tax incentives and subsidies.

Reach New Customers and Increase Competitiveness

Reach new customers and increase competitiveness: Nielsen studies show that 66% of consumers are more likely to spend more on a product that came from a sustainable brand.

Besides, 81% of global consumers strongly believe that companies should help the environment.

Millennials and Generation Z care more about the environment and sustainability than any previous consumer group.

Strengthen the Brand Reputation and Build Public Trust

Another survey by Nielsen shows that millennials are twice as likely as baby boomers to change their habits to reduce environmental impact.

The up-and-coming Generation Z is even more concerned about sustainability.

This shows that corporate brands can increase their value and reputation by focusing on sustainability.

Take Apple, for example.

They have committed to becoming 100% carbon neutral for their products and supply chain by 2030.

I say they’re doing just fine.

Respond to Regulations and Turn Them into Opportunities

A solid sustainability business plan can help companies break into new markets and expand into existing ones.

For example, China’s initiative to fight air pollution promises to create investment opportunities worth more than $3 trillion through the 2030s.

Companies that put sustainability first will be top candidates for new business opportunities.

Can We Make Manufacturing Safer for the Environment?

Yes, we definitely can.

For example, recycling can save money on production, but also reduce the waste companies produce.

Automation also helps improve eco-friendliness by trimming the number of parts rejected by improving consistency. This reduces the amount of scrap even more, while also reducing the amount of materials companies use to fulfill an order.

A drop in waste production benefits the environment, but also the community as less pollution is created that poses a health hazard to citizens.

Apart from improving and optimizing the existing processes, it is also essential to develop new ones that use less harmful materials and generate fewer emissions.

Most importantly, we have to look at the big picture, from the first step of the manufacturing process to the last. This way, instead of spending tons of money on overhauling the entire facility, we can focus on the root causes of waste or emissions.

However, green manufacturing initiatives aren’t only important for the environment’s sake. Using 100% recycled materials and cutting on power use isn’t enough. Every sustainability incentive has to be planned alongside the needs of the community and the company itself.

Otherwise, it won’t be sustainable in the long term.

Sustainable Manufacturing and Robotics: Do They Fit Together?

We’ve seen so far that businesses have to adopt sustainable manufacturing processes to stay competitive, build a reputation with consumers and meet increasingly strict regulations.

To achieve this, many companies turn to robotics, a concept that already saves time, while improving quality and increasing employee safety in many industries.

But what exactly has robotics to do with sustainability and the environment?

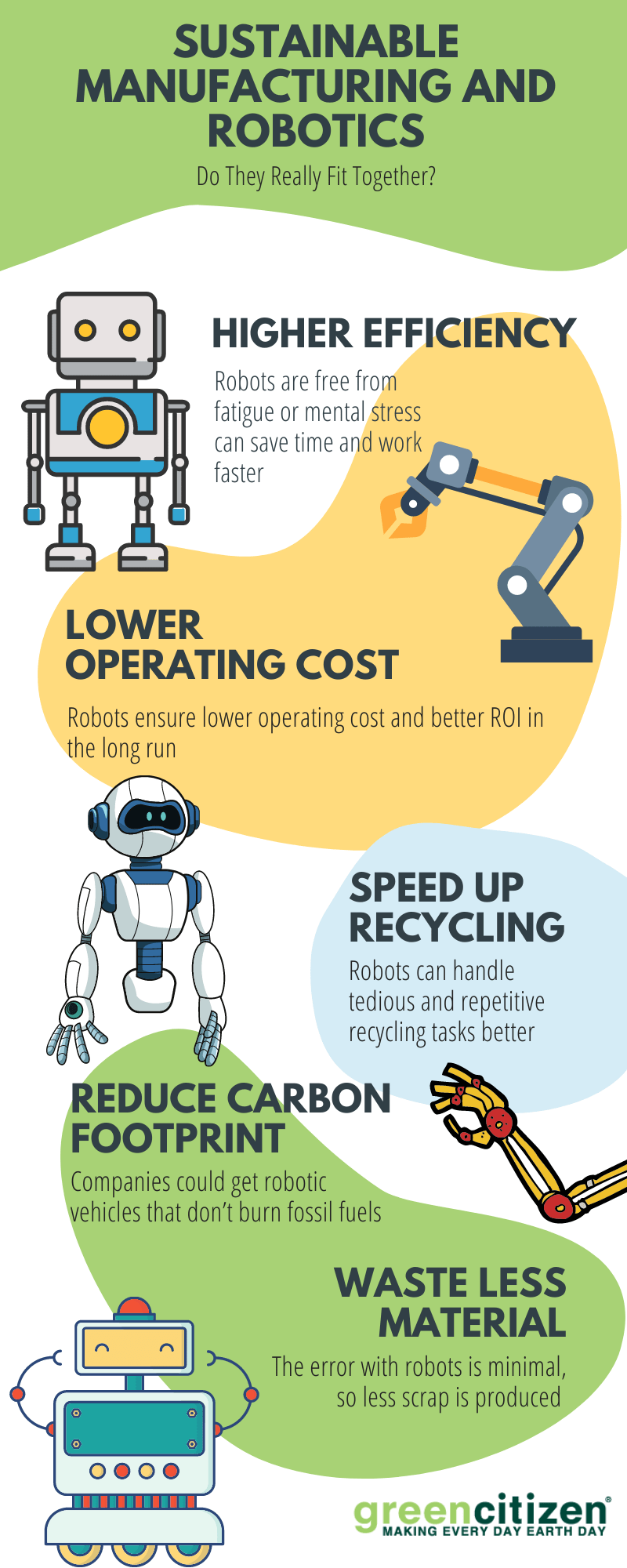

Lower Operating Cost

It’s true that, the setup cost for the manufacturing plant with robots is much higher. However, over the time, we can see more financial benefit as these manufacturing plant will have lower operating cost and almost constant overhead cost.

You could say that the manufacturing plants will get better ROI with the implementation of robotics.

Reduce Carbon Footprint

Factories, ports, and depots are notorious for their carbon footprint. On the other hand, ports like Los Angeles’ TraPac Terminal and the nearby Port Long Beach are already experimenting with automated robots to bring down their carbon emissions.

Instead of using gas-powered trucks and tools, the companies could adopt sustainability business practices that rely on robotic vehicles that don’t burn fossil fuels.

Speed up Recycling

Robots are great in tedious and repetitive tasks, but they absolutely excel in sorting out different materials. This makes them first-class recyclers. They don’t need safety gear and training like human operators do, and their speed is hard to beat.

If humans can sort out 800 items in an hour, robots can sort around 2,000 for the same amount of time.

Now don’t tell me that “these are not the droids you’re looking for”. LOL

Waste Less Material

Robots are already being used in different types of manufacturing lines to improve efficiency with fewer resources. The error with robots is minimal, so less scrap is produced.

Forward-thinking computer companies are already relying on robots to hunt for reusable parts from recycled products. This kind of sustainable manufacture relies on three R’s: Reduce, Reuse, Recycle.

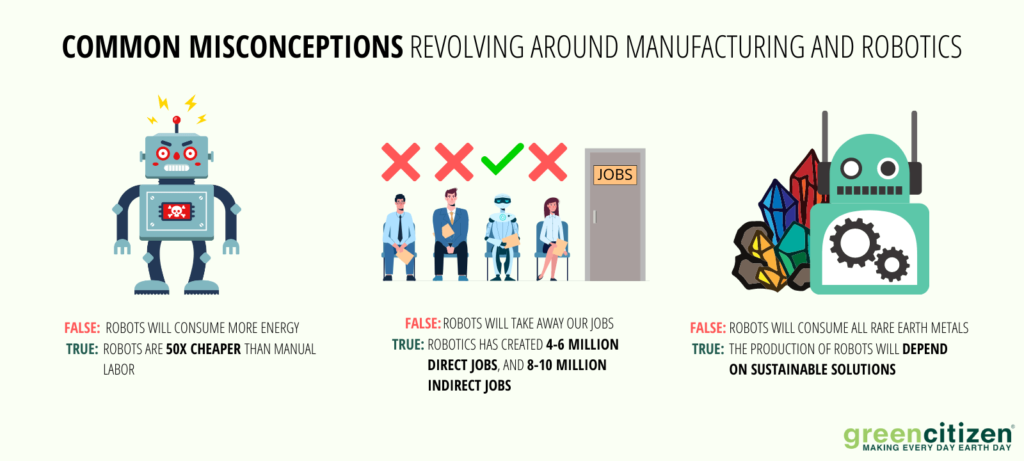

Common Misconceptions Revolving Around Manufacturing and Robotics

Robots will Consume More Energy

Today’s industrial robots recover their initial investment in about 2 years. After that, the hourly cost of a robot is basically the cost of energy it consumes, which is typically $0.3 per hour. This is about 50 times cheaper than the cost of a manual laborer in developed countries.

A typical industrial robot costs 150kWh a day, compared to 56kWh per household in developed countries. However, the amount of energy that industrial robots consume is very small. In the US, for example, there are 50 industrial robots per 56,000 inhabitants.

According to the International Federation of Robotics (IFR), “74 robot units per 10,000 employees is the new average of global robot density in the manufacturing industries.“

A lot of lighting energy is saved since robots don’t need bright lighting to perform their tasks. During the winter months, we can save even more energy, since we don’t need the heating on factory floors which employ industrial robots instead of people.

Robots will Take Away Our Jobs

Research by the IFR reveals that in 2011 between 4 and 6 million direct jobs were created around the world as a result of an increase in the use of robots. On top of it, between 8 and 10 million indirect jobs were created.

These findings provide that instead of killing jobs, robots actually create employment opportunities. Although robotics automation may make some jobs unnecessary, in the bigger picture, many more jobs open up.

Surely, employment in robotics requires a wide range of skills, which might prevent companies from fully embracing automation. But when talking about robotics, we need to make a difference between skill shortage and skill gap:

- A skill shortage is when there are not enough skilled employees to do the job.

- A skill gap is when the existing workforce lacks the required skills to do the job.

Robot producers have an important role in overcoming the skill gap by offering comprehensive training that would increase the employees’ skills and knowledge through certified stages.

Robots will Consume All the Rare Earth Metals

As semiconductors and rare metals are concerned, industrial robots are no different from any machine or computer with high precision and high durability parts. The production of robots will depend on sustainable solutions just like other products.

Besides, just like any other machine or product, we must consider the cost of industrial robots in a life-cycle context. Robots will also become a part of a circular economy and companies will have to find ways to reuse or recycle parts of robots that are not used anymore.

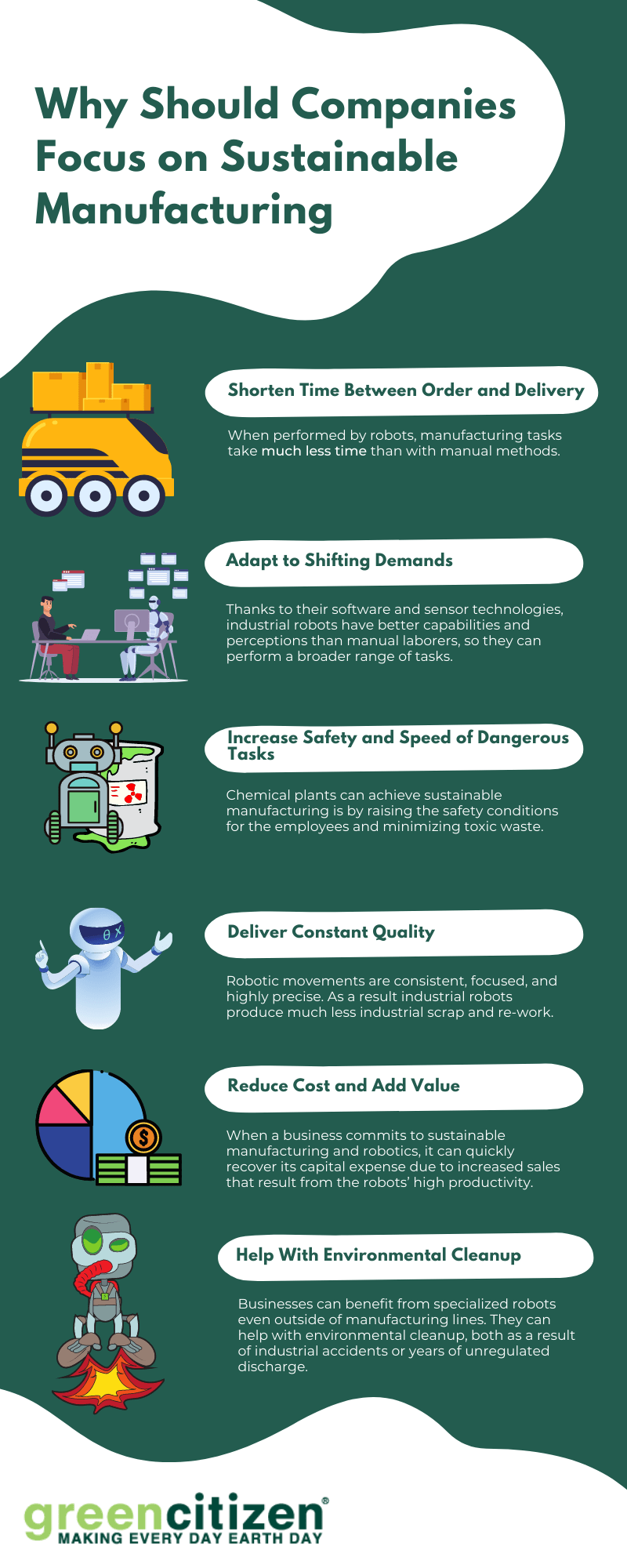

Why Should Companies Focus on Sustainable Manufacturing Through Robotics?

Sustainable manufacturing through robotics and AI has long-term benefits to both the environment, the community, and the company itself. Here’s why we should embrace industrial robots.

Shorten Time Between Order and Delivery

When performed by robots, manufacturing tasks take much less time than with manual methods. At the same time, industrial robots free up skilled workers to perform more complex tasks, optimizing the use of time and money.

Also, robots need very little management oversight — they provide consistent and predictable productivity day after day.

Unlike human employees who work in shifts with peaks and valleys in prediction, robots have a 24-hour production cycle. This is a great advantage in terms of cost reduction and better sustainability.

Adapt to Shifting Demands

Thanks to their software and sensor technologies, industrial robots have better capabilities and perceptions than manual laborers, so they can perform a broader range of tasks.

What is more, programming robots for various tasks has become easier than in the past, so now we can source and train programmers in-house.

As a result, we can automate a robot for a number of tasks in a single setup, which shortens the transition time, training, and space requirements.

And to better respond to variable demands, more robots can be added to a single controller to multiply the speed or scale of a task.

Increase Safety and Speed of Dangerous Tasks

One way chemical plants can achieve sustainable manufacturing is by raising the safety conditions for the employees and minimizing toxic waste. These facilities have massive tanks that need cleaning on a regular basis.

These tanks have small openings and it used to be human workers who had to enter these confined spaces filled with toxic chemicals and volatile gases to clean them up.

It goes without saying, that these brave operators were trained in multiple safety procedures and wore a bulk of safety gear, and had to undergo decontamination each time they left the tanks.

Now, robotic tank cleaners can do it in much less time, using less water, and cleaners.

Most importantly, they remove the danger from human employees and if needed work 24 hours a day with zero stress and fatigue.

Deliver Constant Quality

Robotic movements are consistent, focused, and highly precise. As a result industrial robots produce much less industrial scrap and re-work. Both of these are common in manual labor manufacturing lines due to fatigue, especially late in the shift or by the end of the workweek.

When we introduce robots as a means of sustainable manufacturing, the quality increases without the downsides of finding skilled workers to maintain it.

Reduce Cost and Add Value

When a business commits to sustainable manufacturing and robotics, it can quickly recover its capital expense due to increased sales that result from the robots’ high productivity.

For that matter, it cost less to train and maintain a robotic workforce than human employees. Unlike the conventional forms of automation, we can reposition robots for a wide range of applications.

But the best thing is that the life cycle of a robot can last far beyond its break-even threshold (a point when a machine’s original cost is equal to its revenue.

Access New Resources

In various industries, robots can help tap into new resource locations, for example under the seas or under lakes.

Check out this brilliant example:

According to Fortune magazine, each year logging destroys tree cover about the size of Delaware.

A small Canadian firm from British Columbia has come up with an idea that could slow down deforestation — by replacing forest lumber with submerged trees.

The Sawfish is an underwater logging robot that can access trees drowned in lakes as a result of building dams.

When Ghana’s Akosombo hydroelectric dam was built in 1965, $1 to $2 billion in valuable mahogany, ebony, and other hardwoods was left underwater.

Robots like the Sawfish can safely access and harvest underwater forests, with far less impact on the environment than surface logging.

Help With Environmental Cleanup

Businesses can benefit from specialized robots even outside of manufacturing lines. They can help with environmental cleanup, both as a result of industrial accidents or years of unregulated discharge.

Innovative robotic designs like the plastic-eating Shark drone and Ro-Boat have already proven to be effective in cleaning waterways.

The Ro-Boat uses chemical sensors, GPS, and onboard cameras to detect pollution. Then it sucks in the water, filtering the pollutants before releasing the clean water. This robot can also detect and recover loathing waste, collect debris, and remove sludge deposits from the river bed.

Can Artificial Intelligence (AI) be a Part of the Solution?

There are already many fingers pointed at the development of AI and smart devices. Conservationists are warning that our increasing hunger for e-products causes even more intensive mining of raw materials.

The extraction of nickel, cobalt, and graphite for lithium-ion batteries used in electric cars and smartphones has already left a huge environmental footprint in mineral-rich countries like China, India, and Canada.

However, AI could help businesses achieve sustainable manufacturing by reducing, and even reversing their environmental impact.

Hand in Hand with Robotics

In a joint effort to achieve sustainable manufacturing, AI can help businesses reduce waste and energy use in their production environments. While robotics can enable better accuracy, AI can design more efficient systems.

And by combining several types of AI, such as machine learning, NLP, and computer vision, a company can develop more efficient processes that reduce energy use.

What is more, AI can remove unnecessary steps from the current process by re-engineering processes.

In facilities management, AI can help reuse heat within buildings and minimize heating and cooling losses. We can use AI to optimize lighting and energy needs in buildings by tracking the number of people in a room.

Integrate Renewable Energy

For example, AI can support low-carbon energy systems by integrating renewable energy and energy efficiency, both of which are essential for combating climate change.

In the energy department, AI can use deep predictive capabilities and intelligent grid systems to manage the demand and supply of renewable energy.

By accurately predicting weather patterns, AI can optimize the efficiency of such systems, while cutting costs and unnecessary carbon emissions.

Optimize Supply Chain Logistics

As transportation is concerned, AI has the potential to reduce traffic congestion and improve supply chain logistics, by enabling more and more autonomous vehicles. Eventually, AI will play a pivotal role in the “last mile” delivery that would reduce the need for delivery vehicles.

Through demand forecasting, AI can help businesses reduce the amount of transport needed, which also means a reduced carbon footprint.

Find New Materials

AI can help R&D teams find new materials for products like solar panels, for turning heat into useful electricity or to help find CO2-absorbing materials that could trap the greenhouse gas from the air.

In addition, AI can help us find opportunities to use less raw materials. AI can also employ an open database to develop new low-carbon materials for our products.

Final Thoughts

Robotics and AI are already in use across many industries to increase the productivity of human workers.

However, the same sets of skills that make robots stronger, more precise, and perceptive than humans can help businesses achieve sustainable manufacturing.

Great sustainability initiatives that come with robotics not only benefit the environment, but also the employees, and the company that adapts green manufacturing strategies.

Aided by AI, robots can save both energy and materials, optimize supply chain logistics by moving fossil fuels out of the picture, improve worker safety, and help build a sustainable company image.

Do you share our enthusiasm for the role of robotics and AI in making the world more sustainable?

What is it that you would like to hear more about?

If you have any questions, feel free to ask and leave comments below.