We use Styrofoam all the time—coffee cups, takeout containers, packaging for fragile items. But here’s the thing: most of us don’t actually know what Styrofoam is.

If you’re picturing those white foam plates and cups from your last picnic, you’re not alone. That’s what most people think of when they hear the word. But surprise—that’s not technically Styrofoam!

So, what is Styrofoam, then? And why does it seem to be everywhere?

In this blog, we’re breaking down the facts—what Styrofoam really is, how it’s used, and why it’s such a problem when it comes to waste and recycling. More importantly, we’ll go over the best ways to deal with it so it doesn’t pile up in landfills forever.

Let’s get into it.

What is Styrofoam Made Of?

Before we dive into what Styrofoam is made of, let’s clear up a common mix-up.

Styrofoam isn’t just any foam—it’s a trademarked type of closed-cell extruded polystyrene foam (XPS).

Now, here’s where it gets interesting.

Styrofoam is extruded, not expanded polystyrene foam (EPS). Big difference! EPS is what those lightweight takeout containers and packing peanuts are made of—but that’s a whole other topic.

Image: Dupont

The problem is, people use “Styrofoam” as a catch-all term for any kind of white foam, but it’s actually its own thing.

So, what makes Styrofoam unique? It all comes down to chemistry.

At its core, Styrofoam is made from styrene, a benzene derivative that goes through a polymerization process to form foamed polystyrene. This reaction, carefully controlled, turns liquid hydrocarbons into the lightweight, durable foam we recognize today.

And here’s a fun fact—98% of Styrofoam is just air.

That’s right, all that bulk? Mostly empty space.

In many industries, this material is often referred to as ‘foam board,’ highlighting its common usage in insulation and various applications due to its unique properties.

Note: There is no proper way to recycle #4 Styrofoam or Low-Density Polyethylene foam (LDPE/PELD). The best option is to reuse them as much as possible. If that’s not possible, you need to send them to landfills.

How Styrofoam Came to Be

The story of Styrofoam starts in the 1940s at the Dow Chemical Company, where researchers accidentally discovered a way to turn polystyrene into foam. Like many great inventions, it was a bit of a happy accident—one that led to a material that’s cheap, versatile, and everywhere.

Eventually, the Styrofoam trademark ended up with DuPont, a company well known for pushing the boundaries of material science. With DuPont at the helm, Styrofoam became a household name, used in everything from insulation to crafts (and, of course, a whole lot of packaging).

The journey of Styrofoam, from lab discovery to mass-market staple, is a classic example of scientific curiosity meeting business opportunity.

But as we dig deeper, we hit a bigger question: Is all this convenience worth the environmental cost?

Styrofoam vs. Expanded Polystyrene (EPS): What’s the Difference?

Not all foam is created equal! Styrofoam and Expanded Polystyrene (EPS) may look alike, but their differences go beyond appearances.

In fact, when people say “Styrofoam,” they’re usually talking about EPS—but that’s actually a misconception.

What Is Expanded Polystyrene (EPS)?

Expanded Polystyrene, or EPS as it’s commonly known, is like a cousin to Styrofoam.

Both come from petroleum-based polystyrene, but their formation sets them apart.

Expanded Polystyrene (EPS) is a rigid, closed-cell, thermoplastic foam material crafted from solid polystyrene beads. These beads come from the polymerization of styrene monomer, containing an expansion gas called pentane.

When exposed to steam, these beads expand and fuse, creating a lightweight yet rigid foam. That’s why EPS is commonly used in disposable coffee cups, food containers, and packing materials.

And here’s a key detail: EPS is classified as #6 plastic, meaning it falls under the category of #6 Styrofoam. If you’ve ever flipped over a foam cup or takeout container and seen a little “6” inside the recycling triangle, that’s EPS!

To put it into perspective, Thermocol is a brand of EPS made by BASF, much like Styrofoam is a trademarked form of XPS under DuPont (formerly Dow Chemicals). They might seem interchangeable, but they’re produced through entirely different processes.

Key Differences and Similarities

Both Styrofoam (XPS) and EPS come from polystyrene, but their paths from raw material to final product are very different:

- EPS (Thermocol) – aka #6 Styrofoam: Made by expanding polystyrene beads in a mold using steam, resulting in a looser, more breathable foam. This is what people generally think of as “Styrofoam,” even though it’s not the trademarked kind.

- Styrofoam (XPS): Created by extruding molten polystyrene through a die under pressure, forming a denser, more durable foam with better insulating properties.

At first glance, they might seem like identical twins, but when you look closer, their textures, structures, and uses set them apart.

So, the next time you grab a foam cup and call it Styrofoam, just know—you’re probably holding #6 EPS!

Here’s a quick comparison table to highlight the key differences and similarities between Styrofoam and EPS for better clarity.

| Styrofoam (XPS) | Expanded Polystyrene (EPS) | |

|---|---|---|

| Base Material | Polystyrene | Polystyrene |

| Manufacturing Process | Extrusion | Expansion |

| Texture | Finer, closed-cell structure | Coarser, open-cell structure |

| Insulating Properties | Higher | Lower |

| Brand | Dow Chemicals | BASF (Thermocol) |

| Environmental Impact | Similar, derived from petroleum | Similar, derived from petroleum |

Through this comparative lens, we can understand the differences between Styrofoam and EPS, despite their common ancestry.

Types of Styrofoam: Exploring The Varieties

Not all Styrofoam is the same. It comes in different forms, each with unique properties and uses. Understanding these variations helps us make smarter choices—whether for construction, packaging, or everyday applications.

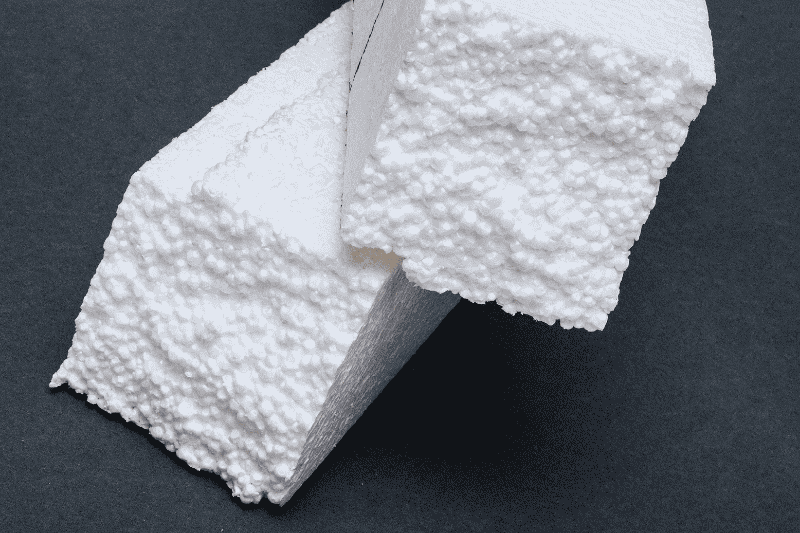

Extruded Polystyrene Foam (XPS) – The True Styrofoam

This is the real Styrofoam, known for its smooth texture and excellent insulation properties. It’s widely used in construction, especially for insulation, and is also a go-to material for crafting and modeling projects.

Expanded Polystyrene Foam (EPS) – The Misunderstood Cousin

EPS isn’t technically Styrofoam, but people often mistake it for one. It has a rougher texture, is lighter than XPS, and is commonly used in packaging to protect fragile items.

If you’ve ever received a package with foam inserts or eaten from a foam takeout container, you’ve likely encountered EPS. It’s also classified as #6 plastic.

Low-Density Polyethylene Foam (LDPE) – The #4 Styrofoam

While not polystyrene-based, LDPE foam (also known as #4 Styrofoam) is another common material mistaken for Styrofoam. It’s softer, flexible, and more durable, often used for protective padding, pool noodles, and industrial packaging.

Unlike EPS or XPS, LDPE foam is more recyclable, though options are still limited.

High-Impact Polystyrene (HIPS) – The Tough One

This version of polystyrene is blended with rubber, making it stronger and more durable. It’s often used in appliance parts, signage, and even medical trays, where toughness is key.

Styrofoam Insulation Boards – Built for Protection

A specialized form of XPS, these rigid boards are designed for thermal insulation in buildings, helping regulate indoor temperatures by blocking heat and cold. They’re a staple in the construction industry.

Each of these materials serves a distinct purpose, proving that Styrofoam is more than just coffee cups and takeout containers!

Identifying Different Types of Styrofoam

With so many types of Styrofoam floating around, how do you tell them apart? The good news is, each type has distinct characteristics that make identification easier.

Here’s what to look for:

- Texture: XPS has a smooth texture, while EPS has a rough, bead-like texture. HIPS, on the other hand, feels tougher and more rigid.

- Color: Styrofoam types may sport different colors which can be a cue. For instance, XPS is often blue or pink, while EPS is usually white.

- Application: The use of the foam can also hint at its type. For insulation, XPS and insulation boards are common, while EPS is a regular for packaging.

- Density and Flexibility: XPS and insulation boards are denser and less flexible compared to EPS.

The more we learn about Styrofoam, the better we can understand its impact—and how to make smarter choices for sustainability.

Pretty cool, right?

How GreenCitizen Recycles Styrofoam Responsibly

At GreenCitizen’s Burlingame EcoCenter, we specialize in recycling #6 Styrofoam (Expanded Polystyrene or EPS) using a thermal densification process.

Instead of sending discarded foam to landfills, we transform it into valuable raw materials that can be repurposed into new products.

Step-by-Step Styrofoam Recycling at GreenCitizen

1. Collection: Drop-Off and Business Pick-Up Services

We accept clean, dry EPS Styrofoam—commonly found in packaging materials, insulation, and protective foam.

To ensure contamination-free recycling:

- No food containers are accepted.

- No labels, glue, tape, or other film coatings on the foam.

Individuals can drop off their Styrofoam at the Burlingame EcoCenter Monday to Friday, 10 AM – 6 PM. Businesses with large amounts of Styrofoam can schedule a pickup service.

There’s a $5 charge per 30-gallon bag, but packing peanuts and unpopped bubble wrap are accepted for free.

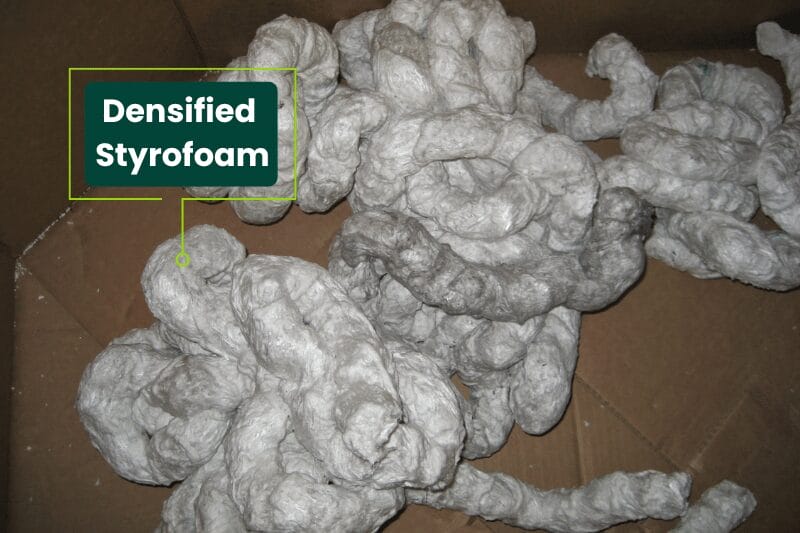

2. Shredding & Thermal Densification

Once collected, the Styrofoam is shredded into small pieces to increase its surface area. It then undergoes a thermal densification process, where heat is applied to compact the foam into dense ingots or blocks, reducing its original volume by up to 1/90th.

3. Processing Into Recycled Materials

The densified Styrofoam is then processed into polystyrene pellets, which manufacturers use to create new products like:

- Insulation panels

- Ceiling moldings

- Construction materials

- Public benches

- Toys, plant pots, and surfboards

Some materials are also repurposed into recycled plastic resins (rPS or rLDPE), which can be used in new product manufacturing or blended with virgin plastic resins.

Why GreenCitizen’s Styrofoam Recycling Is Different

- No Landfill Waste: All EPS foam is fully recycled, never incinerated or landfilled.

- Local Processing: We process Styrofoam in the Bay Area, reducing transportation emissions.

- Energy-Efficient Methods: Our thermal densification process minimizes waste and emissions.

- Circular Economy Approach: We work with manufacturers to reintegrate recycled Styrofoam into production, reducing the demand for new plastic materials.

- Easy & Convenient: We offer both individual drop-offs and business pickups to make Styrofoam recycling accessible for everyone.

There Is No Such Thing as Styrofoam Cups!

You grab a foam cup of coffee, and the word “Styrofoam” pops into your head. Sounds familiar, right?

Well, here’s a little twist—Styrofoam cups don’t exist!

It’s one of the most common misconceptions out there. The foam cups, takeout containers, and packaging materials we see every day? They’re not actually Styrofoam™.

When professionals in construction talk about Styrofoam, they mean something completely different. The real Styrofoam, trademarked by DuPont, isn’t used for disposable products. Instead, it’s a rigid insulation material found in buildings, often colored blue or grey.

So, what’s the white foam in coffee cups and food containers? That’s Expanded Polystyrene (EPS). A closer look at EPS reveals tiny gaps between the foam cells, which make it lightweight but also prone to air and moisture seepage over time. This is why it lacks the compression strength of real Styrofoam—ever accidentally crushed a foam cup just by gripping it too hard?

That’s why!

Now that the myth is busted, the next time you pick up a foam cup, you’ll know the truth. It’s EPS, polystyrene, or just foam—but definitely not Styrofoam™.

Can You Recycle All Types of Styrofoam?

Recycling feels like a step in the right direction—giving materials a second life instead of letting them pile up in landfills. But when it comes to recycling styrofoam, the reality isn’t so simple. Not all types are equally recyclable, and understanding the differences can help us make better choices.

Despite the technical recyclability of polystyrene, the market demand for recycled polystyrene products is limited, and the high costs involved in the recycling process further complicate efforts.

Recycled polystyrene is often used to create packaging for other materials, but its applications are restricted, especially in food-related contexts due to health concerns.

Additionally, recycling facilities may not accept certain types of polystyrene, and the lack of demand for recycled polystyrene is a significant barrier to effective recycling efforts.

Recyclability of Styrofoam: What’s Possible and What’s Not?

The recyclability of Styrofoam depends entirely on the type. Some can be processed and reused, while others are far more challenging to recycle.

#6 Styrofoam (Expanded Polystyrene – EPS) Can Be Recycled

Yes, you read that right!

EPS is recyclable—but here’s the catch: not every recycling facility accepts it.

Luckily, organizations like GreenCitizen are working to change that. If you’re in the San Francisco Bay Area, you can bring your EPS foam to GreenCitizen’s Burlingame Eco Center for responsible recycling. Instead of ending up in a landfill, EPS can be processed into new products like picture frames, insulation, and more.

#4 Styrofoam (LDPE Foam) Often Ends Up in Landfills

Now, here’s the tough part. Low-Density Polyethylene (LDPE) foam, also known as #4 Styrofoam, is much harder to recycle. Unlike EPS, LDPE foam lacks widespread recycling infrastructure, so most of it ends up in landfills—where it sits for centuries, refusing to decompose.

The low recycling rates of Styrofoam paint a grim picture. As landfills fill up, Styrofoam waste leaches chemicals into the soil and contributes to greenhouse gas emissions. Without better recycling systems, we’re stuck with a material that just won’t go away.

This contrast between EPS and LDPE recycling highlights an urgent issue: we need better recycling facilities, more awareness, and smarter choices when it comes to using and disposing of Styrofoam.

By understanding which types can be recycled, we can take action—choosing responsible disposal options, supporting businesses that offer Styrofoam recycling, and advocating for stronger recycling programs.

The more we learn, the better we can push for a future where every piece of Styrofoam finds its way into a recycling loop instead of a landfill.

Recycling Right: What We’ve Learned About Styrofoam

TL;DR about Styrofoam—it’s not just any foam, but a trademarked insulation material that’s often confused with disposable packaging. Along the way, we’ve explored its close relatives, EPS (#6 Styrofoam) and LDPE (#4 Styrofoam), each with very different recyclability challenges.

The key takeaway? Not all Styrofoam is created equal, and not all of it can be easily recycled. While EPS can be processed at specialized facilities like GreenCitizen, LDPE foam often ends up in landfills due to limited recycling options.

This makes mindful usage and responsible disposal more important than ever. The more we educate ourselves, push for better recycling infrastructure, and choose sustainable alternatives, the closer we get to reducing Styrofoam waste.

Every small action—whether it’s recycling correctly, spreading awareness, or cutting down on single-use foam—adds up. The next time you come across Styrofoam, think beyond the convenience and consider its impact. A greener future starts with informed choices!