Styrofoam is not the white foam cups and takeout containers most people picture. Styrofoam™ is a trademarked brand of extruded polystyrene (XPS) foam used mainly for building insulation, while many everyday “foam” products are expanded polystyrene (EPS) or other plastics that only look similar.

In this guide, you’ll learn what Styrofoam is, what it’s made of, how it differs from EPS, how to identify common foam materials, and what recycling options actually exist, including how GreenCitizen recycles clean EPS in the Bay Area.

Key Takeaways

- Styrofoam is a Brand, Not a Cup: Real Styrofoam™ is a trademarked, extruded insulation material (XPS) usually found in construction. The white, beaded foam used for cups and packaging is actually Expanded Polystyrene (EPS).

- Why Curbside Recycling Fails: Because EPS foam is 98% air and extremely bulky, standard municipal recycling trucks cannot efficiently transport it. It requires specialized thermal densification to be recycled effectively.

- Spot the #6 Symbol: GreenCitizen specializes in recycling clean, white #6 EPS packaging foam. However, flexible foam (LDPE #4) and food-contaminated containers cannot be processed and must be disposed of differently.

What Is Styrofoam?

Styrofoam™ is a trademarked brand of extruded polystyrene (XPS) foam insulation used mainly in construction. Most foam cups, takeout containers, and packaging people call “styrofoam” are usually expanded polystyrene (EPS), which is a different material made in a different way.

Image: Dupont

What Is Styrofoam Made of?

Styrofoam is made of styrene, a petroleum-based substance refined into a polymer called polystyrene. Through an extrusion process, 98% air is introduced to the plastic, creating a lightweight, moisture-resistant, closed-cell foam known as Extruded Polystyrene (XPS).

Before we dive deeper, we must look at the chemistry. Styrofoam is not found in nature; it is a synthetic aromatic hydrocarbon polymer.

At its core, it is made from styrene, a derivative of benzene. Through a process called polymerization, liquid hydrocarbons are converted into the solid foam we recognize. Because the material is 98% air, it is an incredible thermal insulator, which is why “true” Styrofoam is used in construction to keep buildings warm or cool.

Note on Toxicity: Because it is petroleum-based, there are concerns regarding styrene leaching, which is why distinguishing between construction-grade Styrofoam and food-grade EPS is vital for health and safety.

Note: There is no proper way to recycle #4 Styrofoam or Low-Density Polyethylene foam (LDPE/PELD). The best option is to reuse them as much as possible. If that’s not possible, you need to send them to landfills.

The History of Styrofoam: How It Came to Be

Styrofoam was invented by researchers at the Dow Chemical Company in the 1940s. While attempting to create a flexible electrical insulator, they accidentally discovered a method to extrude polystyrene into a lightweight foam. The trademark is currently owned by DuPont.

The story is a classic case of scientific serendipity. In 1941, Ray McIntire and the Dow Chemical team were trying to find a replacement for rubber during World War II. instead, they found a way to “extrude” (push through a mold) polystyrene.

This resulted in a rigid, water-resistant foam that was perfect for buoyancy (life rafts) and eventually insulation. It became a household name, much like “Kleenex” is used for tissues, which leads us to the biggest confusion in the plastic world today.

Styrofoam vs. Expanded Polystyrene (EPS): What is the Difference?

The difference between Styrofoam and EPS is the manufacturing process. Styrofoam is Extruded Polystyrene (XPS), created by pushing molten plastic through a die for a smooth, closed-cell finish. EPS is Expanded Polystyrene, made by steaming beads until they fuse, resulting in a rough, white, bead-like texture.

What Is Expanded Polystyrene (EPS)?

Expanded Polystyrene, or EPS as it’s commonly known, is like a cousin to Styrofoam.

Both come from petroleum-based polystyrene, but their formation sets them apart.

Expanded Polystyrene (EPS) is a rigid, closed-cell, thermoplastic foam material crafted from solid polystyrene beads. These beads come from the polymerization of styrene monomer, containing an expansion gas called pentane.

When exposed to steam, these beads expand and fuse, creating a lightweight yet rigid foam. That’s why EPS is commonly used in disposable coffee cups, food containers, and packing materials.

And here’s a key detail: EPS is classified as #6 plastic, meaning it falls under the category of #6 Styrofoam. If you’ve ever flipped over a foam cup or takeout container and seen a little “6” inside the recycling triangle, that’s EPS!

To put it into perspective, Thermocol is a brand of EPS made by BASF, much like Styrofoam is a trademarked form of XPS under DuPont (formerly Dow Chemicals). They might seem interchangeable, but they’re produced through entirely different processes.

Key Differences and Similarities

Both Styrofoam (XPS) and EPS come from polystyrene, but their paths from raw material to final product are very different:

- EPS (Thermocol) – aka #6 Styrofoam: Made by expanding polystyrene beads in a mold using steam, resulting in a looser, more breathable foam. This is what people generally think of as “Styrofoam,” even though it’s not the trademarked kind.

- Styrofoam (XPS): Created by extruding molten polystyrene through a die under pressure, forming a denser, more durable foam with better insulating properties.

At first glance, they might seem like identical twins, but when you look closer, their textures, structures, and uses set them apart.

So, the next time you grab a foam cup and call it Styrofoam, just know—you’re probably holding #6 EPS!

Here’s a quick comparison table to highlight the key differences and similarities between Styrofoam and EPS for better clarity.

| Styrofoam (XPS) | Expanded Polystyrene (EPS) | |

|---|---|---|

| Base Material | Polystyrene | Polystyrene |

| Manufacturing Process | Extrusion | Expansion |

| Texture | Finer, closed-cell structure | Coarser, open-cell structure |

| Insulating Properties | Higher | Lower |

| Brand | Dow Chemicals | BASF (Thermocol) |

| Environmental Impact | Similar, derived from petroleum | Similar, derived from petroleum |

Types of Styrofoam: Exploring The Varieties

Many materials get mislabeled as “styrofoam,” including EPS (expanded polystyrene), XPS (Styrofoam™ insulation board), and sometimes polyethylene (PE) foam used for protective padding. Grouping these under one name causes disposal mistakes, because recyclability and accepted drop-off rules vary by material.

To recycle right, you need to identify the foam correctly:

- Extruded Polystyrene (XPS): The “Real” Styrofoam. Smooth, colored (Blue/Pink), used in walls and roofs.

- Expanded Polystyrene (EPS): The “Fake” Styrofoam. White, composed of tiny beads. This is your takeout container and packing block.

- Low-Density Polyethylene (LDPE) #4: This is spongy, flexible foam often used to wrap electronics or as “pool noodles.” It is not Styrofoam and requires different recycling channels.

- High-Impact Polystyrene (HIPS): A rubber-modified polystyrene used in durable goods like appliance liners.

How To Identify EPS, XPS, And Other Foams

To identify foam, check the texture (EPS looks like fused beads, XPS looks smooth), the typical use (XPS is usually insulation board), and any resin code stamped on non-foamed plastic parts.

Correct identification matters because many curbside programs reject foam even when the base plastic is technically recyclable.

Is Styrofoam Recyclable?

“Styrofoam” recycling depends on what you actually have. EPS foam can be recycled at specialized drop-offs (not usually curbside), while XPS insulation and PE foams may have fewer local options and often require construction-specific or specialty recycling routes. Always identify the material first, then check local acceptance rules.

The short answer is: Yes, Styrofoam is recyclable, but not in your blue bin.

Because EPS takes up massive amounts of space but weighs very little, waste management companies lose money trying to transport it. It creates a “false economy” for standard recyclers.

However, just because your city won’t take it doesn’t mean it should go to the landfill.

The #4 vs. #6 Dilemma

- #6 EPS: Highly recyclable at specialized centers (like ours).

- #4 LDPE Foam: Much harder to find recycling markets for. Unfortunately, most LDPE foam ends up in landfills because the infrastructure to process it is scarce.

How GreenCitizen Recycles Styrofoam Responsibly

GreenCitizen accepts clean, dry EPS (expanded polystyrene) foam and processes it using shredding and thermal densification to reduce volume and convert it into reusable polystyrene raw material. Clear acceptance rules (no food contamination, no tape/labels) help ensure the output can be turned into new products instead of landfilled.

At our Burlingame EcoCenter, we tackle the “Styrofoam problem” head-on. We don’t want this material taking up space in landfills for 500 years.

Step-by-Step Styrofoam Recycling at GreenCitizen

1. Collection: Drop-Off and Business Pick-Up Services

We accept clean, dry EPS Styrofoam—commonly found in packaging materials, insulation, and protective foam.

To ensure contamination-free recycling:

- No food containers are accepted.

- No labels, glue, tape, or other film coatings on the foam.

Individuals can drop off their Styrofoam at the Burlingame EcoCenter Monday to Friday, 10 AM – 6 PM. Businesses with large amounts of Styrofoam can schedule a pickup service.

There’s a $5 charge per 30-gallon bag, but packing peanuts and unpopped bubble wrap are accepted for free.

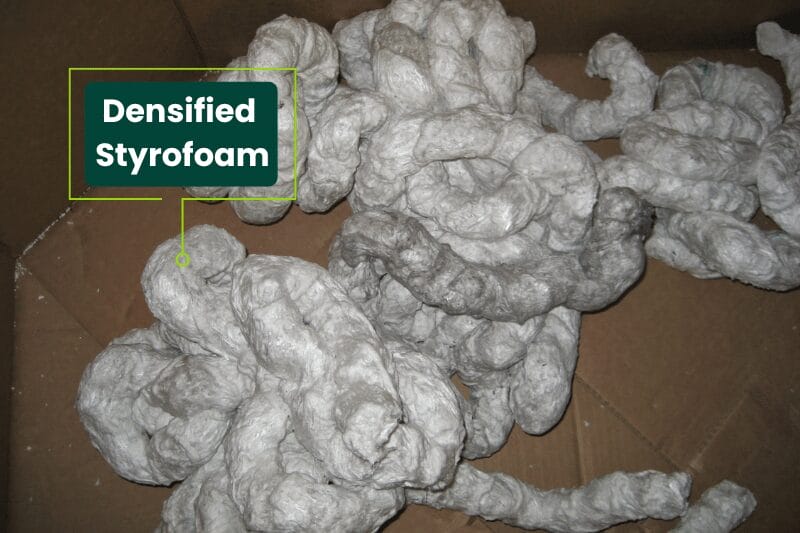

2. Shredding & Thermal Densification

Once collected, the Styrofoam is shredded into small pieces to increase its surface area. It then undergoes a thermal densification process, where heat is applied to compact the foam into dense ingots or blocks, reducing its original volume by up to 1/90th.

3. Processing Into Recycled Materials

The densified Styrofoam is then processed into polystyrene pellets, which manufacturers use to create new products like:

- Insulation panels

- Ceiling moldings

- Construction materials

- Public benches

- Toys, plant pots, and surfboards

Some materials are also repurposed into recycled plastic resins (rPS or rLDPE), which can be used in new product manufacturing or blended with virgin plastic resins.

Why GreenCitizen’s Styrofoam Recycling Is Different

- No Landfill Waste: All EPS foam is fully recycled, never incinerated or landfilled.

- Local Processing: We process Styrofoam in the Bay Area, reducing transportation emissions.

- Energy-Efficient Methods: Our thermal densification process minimizes waste and emissions.

- Circular Economy Approach: We work with manufacturers to reintegrate recycled Styrofoam into production, reducing the demand for new plastic materials.

- Easy & Convenient: We offer both individual drop-offs and business pickups to make Styrofoam recycling accessible for everyone.

Styrofoam Isn’t What You Think: Here’s The Truth (And What To Do Next)

Styrofoam isn’t the catch-all “white foam” material most people think it is. Styrofoam™ is a trademarked form of extruded polystyrene (XPS) insulation, while the foam cups, takeout clamshells, and protective packaging that usually get mislabeled as “styrofoam” are typically expanded polystyrene (EPS). Once you know that difference, everything else becomes easier, because identifying the material is the first step to disposing of it correctly.

Here’s the practical takeaway: if it’s clean, dry EPS, it may be recyclable through specialized programs, and that’s exactly where GreenCitizen comes in, turning bulky foam into usable raw material through densification instead of letting it drift into landfills. If it’s food-soiled foam, mixed materials, or insulation board, recycling options are often limited and highly location-dependent, so your best move is to reduce use, reuse when possible, and follow local acceptance rules.

The next time you hear “Styrofoam,” think like a materials detective: What foam is it really, what was it used for, and is it clean enough to be processed? Answer those three questions, and you’ll avoid wish-cycling, prevent contamination, and make choices that actually reduce waste instead of just relocating it.