Plastic is everywhere—our grocery bags, water bottles, and even packaging for the tiniest gadgets.

But have you ever wondered what happens to that empty plastic bottle or plastic bag after you toss it in the recycling bin? You’re not alone. Many people assume their recycled plastic magically turns into something new, but the reality is much more complex.

With plastic pollution choking our oceans and landfills, understanding how recycling works is more important than ever.

Does your plastic packaging actually get recycled? Or does it end up somewhere unexpected? Let’s uncover the fascinating journey of recycled plastic.

The Global Scale of Plastic Production and Recycling

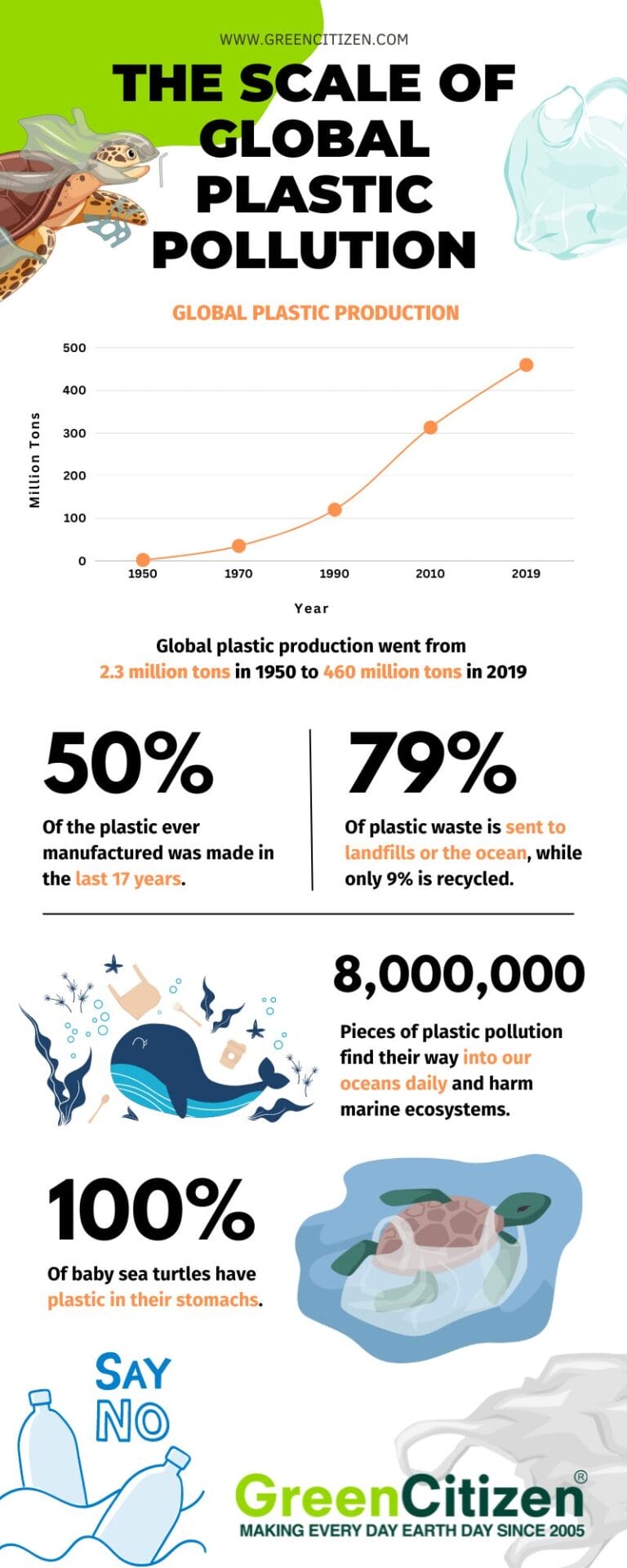

Every year, we produce around 400 million metric tons of plastic, and this amount is expected to double by 2050. In the United States, each person uses about 286 pounds (130 kilograms) of plastic annually, one of the highest per-person rates in the world.

Despite this, the ability to recycle plastic significantly trails behind the rate at which it’s produced.

Globally, only 9% of all plastic waste ever made has been recycled, according to the United Nations. The rest ends up in landfills—about 79%—or is burned, contributing 12% to emissions. In 2021, the United States recycled just 5-6% of its plastic waste, while Germany achieved an impressive 56%. India’s informal recycling systems also help the country recycle nearly 60% of its plastic waste.

The gap between production and recycling is staggering. For example, in 2020, the U.S. generated 35 million metric tons of plastic waste, but only 2.5 million metric tons were recycled. The rest contributes to landfill overflow, pollution, and marine debris, with about 8 million metric tons of plastic entering the oceans every year.

This imbalance isn’t just an environmental problem. Differences in recycling systems, demand for recycled plastic, and contamination in the waste stream make it harder to recycle efficiently. Addressing these challenges is critical to reducing the burden plastic waste puts on our planet.

What Actually Happens After Collection: The Plastic Recycling Process

Collection and Transport

Once you place plastic into the recycling bin, it’s collected by municipal curbside programs or private waste management companies. These programs gather recyclable materials from households, schools, and businesses.

The collected materials are transported to Material Recovery Facilities (MRFs), where they’re prepared for further processing. During transport, careful handling is crucial to avoid contamination or damage that could render the materials unrecyclable.

Once at the MRF, plastics are separated from other recyclables like glass, paper, and metals. This step ensures the collected materials are sorted correctly for the next stages of recycling.

Sorting

At the facility, plastics undergo sorting to separate recyclable materials from contaminants and non-recyclable items.

This step can involve manual labor, where workers identify and remove problematic materials such as food residue or non-recyclable plastics. Increasingly, facilities use advanced technologies like optical scanners, which can identify different types of plastics based on their resin identification codes, and magnets to separate metals.

Proper sorting ensures higher-quality recycled material, reduces waste, and makes the entire recycling process more efficient. Without accurate sorting, the resulting recycled plastic might not meet the quality standards needed for reuse.

Cleaning and Washing

After sorting, plastics are cleaned to remove contaminants such as labels, adhesives, and food residues. This step is essential because even small amounts of contaminants can disrupt the recycling process. The cleaning process often uses water and specialized machinery to ensure thorough results.

However, the environmental impact of this step, particularly its water and energy usage, has sparked concerns and controversies.

To address this, many facilities are adopting innovative water-recycling systems and energy-efficient methods to minimize their ecological footprint while maintaining the quality of the recycled materials.

Shredding and Resizing

Once cleaned, the plastics are shredded into smaller pieces, known as flakes or pellets. Shredding reduces the size of the plastic, making it easier to handle, store, and process in subsequent stages.

These smaller pieces are also inspected to ensure they are free of any remaining contaminants. Shredding ensures consistency in the melting process and ensures uniformity in the final recycled products.

Shredded plastics are versatile and can be directly used in manufacturing or further processed into raw materials.

Melting and Pelletizing

In the final stage, shredded plastic is melted and reshaped into small pellets, often called resin or plastic resin.

These pellets are the raw materials used to create a wide variety of new products, from water bottles and plastic packaging to textile fibers and construction materials. The melting process occurs at high temperatures and requires specialized machinery to ensure that the pellets are uniform in size and quality.

This uniformity is crucial for manufacturers who rely on these pellets to produce durable and consistent products.

Key Players in the Recycling Chain

The recycling process involves a coordinated effort among various entities. Local recycling facilities and Material Recovery Facilities (MRFs) handle collection, sorting, and initial processing.

Private companies often take over for advanced recycling stages, such as pelletizing and repurposing materials. On a global scale, major organizations and multinational corporations play a significant role in developing innovative recycling technologies and creating demand for recycled materials. In fact, waste management is a $1.2 trillion global industry.

Together, these players ensure that recycled plastics are transformed into new products, reducing waste and closing the loop on plastic use.

What Products Are Made from Recycled Plastic?

Common Recycled Plastic Products

Recycled plastic is used to create a wide range of everyday items.

For example, plastic beverage bottles are often transformed into new bottles, ensuring a continuous lifecycle. Textile fibers, like polyester used in clothing, frequently come from recycled plastics, especially PET (#1 plastic).

Beyond clothing, furniture and construction materials like decking boards or pipes are other common applications. Even plastic packaging, such as containers and wrapping, can include recycled content, reducing the demand for virgin plastic.

Closed-Loop vs. Downcycling

Plastic recycling generally falls into two categories: closed-loop and downcycling.

In closed-loop recycling, materials are reused to make the same product—for instance, a plastic water bottle becoming another bottle. This process maintains the material’s original quality.

Downcycling, on the other hand, turns high-grade plastic into lower-quality items, such as turning PET bottles into carpet fibers or insulation materials.

While downcycling extends the plastic’s life, the material eventually becomes unusable for further recycling.

Innovative Uses

The rise of technology and design innovations has opened up exciting possibilities for recycled plastic.

For example, 3D printing filaments made from recycled PET provide sustainable options for creating prototypes and products. Composite lumber, a mix of recycled plastic and wood fibers, is a durable alternative for outdoor construction projects like fences or decks.

Some companies even use recycled plastics to create eye-catching products like shoes, backpacks, and high-end furniture. These innovative applications demonstrate the potential for recycled plastic to address environmental challenges creatively.

Can All Types of Plastics Be Recycled?

Resin Identification Codes

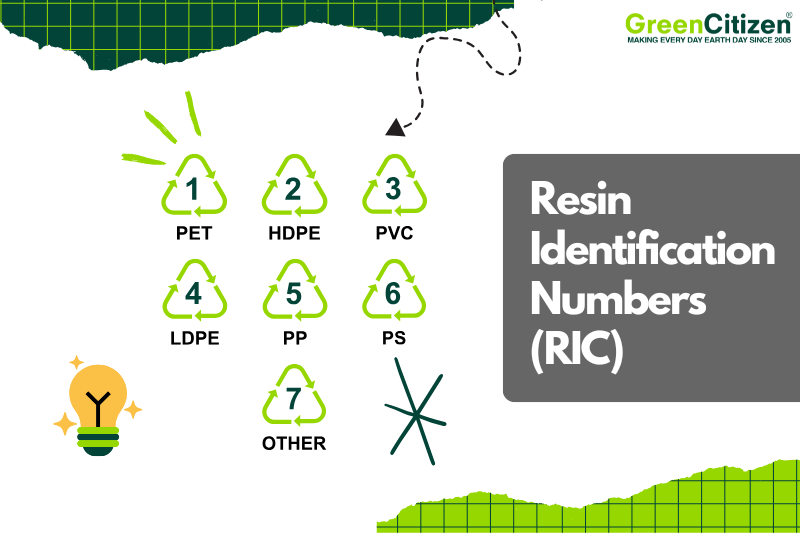

Plastics are categorized into seven types based on their Resin Identification Codes (RIC), which are the small recycling numbers typically surrounded by a triangular arrow symbol.

You can usually find this symbol on the bottom or side of plastic containers, bottles, or packaging. The RIC indicates the type of resin used to make the plastic and helps determine whether it can be recycled.

- PET (1): Common in water bottles and food containers, PET is widely recycled into new bottles or polyester fibers.

- HDPE (2): Found in milk jugs and detergent bottles, HDPE is durable and easily recyclable.

- PVC (3): Often used in pipes and vinyl, PVC is difficult to recycle due to its chemical composition.

- LDPE (4): Seen in plastic bags and squeezable bottles, LDPE recycling is limited but growing in some areas.

- PP (5): Used in food containers and bottle caps, PP is recyclable in specific facilities.

- PS (6): Commonly known as Styrofoam, PS is lightweight and rarely recycled due to contamination and cost issues.

- Other (7): Includes mixed plastics like polycarbonate, which are the hardest to recycle and often non-recyclable.

Understanding these numbers and symbols can help you identify recyclable plastics and make informed choices about disposal. Check with your local recycling program to confirm which types they accept.

Which Types Are Widely Accepted?

Among the seven types, PET (1) and HDPE (2) are the most widely accepted by recycling facilities. These plastics are used in products like water bottles, milk jugs, and detergent containers. Their high demand and straightforward recycling process make them preferable.

Other plastics, like LDPE (4) and PP (5), are accepted in some facilities but require specific systems due to their lower demand or more complex processing needs.

Challenges with Certain Plastics

Not all plastics are easy to recycle. PVC (3), PS (6), and Other (7) are less frequently recycled due to contamination risks and market demand issues.

For example, Styrofoam (PS) is lightweight and often contaminated, making it costly to process. Mixed plastics under category 7 lack consistency in material, further complicating recycling efforts.

Contamination, like food residue or incorrect disposal, lowers the quality of recycled material, reducing its usability for new products and leading to higher waste rates.

The Fate of Plastic That Isn’t Recycled

Landfills

Plastic waste that isn’t recycled often ends up in landfills, where it occupies vast amounts of space. Globally, an estimated 79% of plastic waste is sent to landfills. Unlike organic materials, plastic doesn’t decompose easily.

Instead, it can take anywhere from 500 to 1,000 years to break down, depending on the type of plastic and environmental conditions. During this long degradation process, plastics release harmful microplastics into the soil, which can contaminate water sources and agricultural land.

These microplastics can enter food chains, indirectly affecting human health.

In addition to their massive space requirements, plastics in landfills can release methane, a potent greenhouse gas, as they degrade—further contributing to climate change. Landfill leachate, a toxic liquid formed by decomposing waste, can also seep into surrounding soil and waterways, carrying harmful chemicals with it.

Incineration

Some plastics are disposed of through incineration, which involves burning waste to reduce its volume. While this method can generate energy, it comes with significant environmental concerns.

Incineration releases toxic gases, including dioxins and furans, which contribute to air pollution and pose health risks to nearby communities. Additionally, the ash left behind contains heavy metals and other harmful residues, requiring specialized disposal methods.

Modern incineration plants have adopted advanced technologies to capture and filter harmful emissions, reducing their environmental impact.

For instance, scrubbers remove acidic gases, while baghouse filters trap fine particulates. Despite these improvements, incineration remains controversial due to its high energy consumption and lingering risks of pollution. However, in some regions, energy generated from burning plastic is used to power nearby facilities, creating a partial benefit to this disposal method.

Export to Other Countries

For decades, wealthier nations have exported contaminated or low-grade plastic waste to developing countries.

These practices surged until 2018, when China’s National Sword policy banned most plastic imports. This shift left many countries scrambling to manage their waste domestically.

Unfortunately, exported plastics still end up in nations with limited recycling infrastructure, leading to improper disposal. Open burning, unregulated dumping, and mismanagement in these regions exacerbate environmental and health problems for local populations.

The economic cost of accepting foreign plastic waste often outweighs any benefits, as developing nations struggle with pollution and public health crises. The long-term damage to ecosystems and communities makes this practice unsustainable and highlights the urgent need for better global waste management systems.

Ocean Pollution

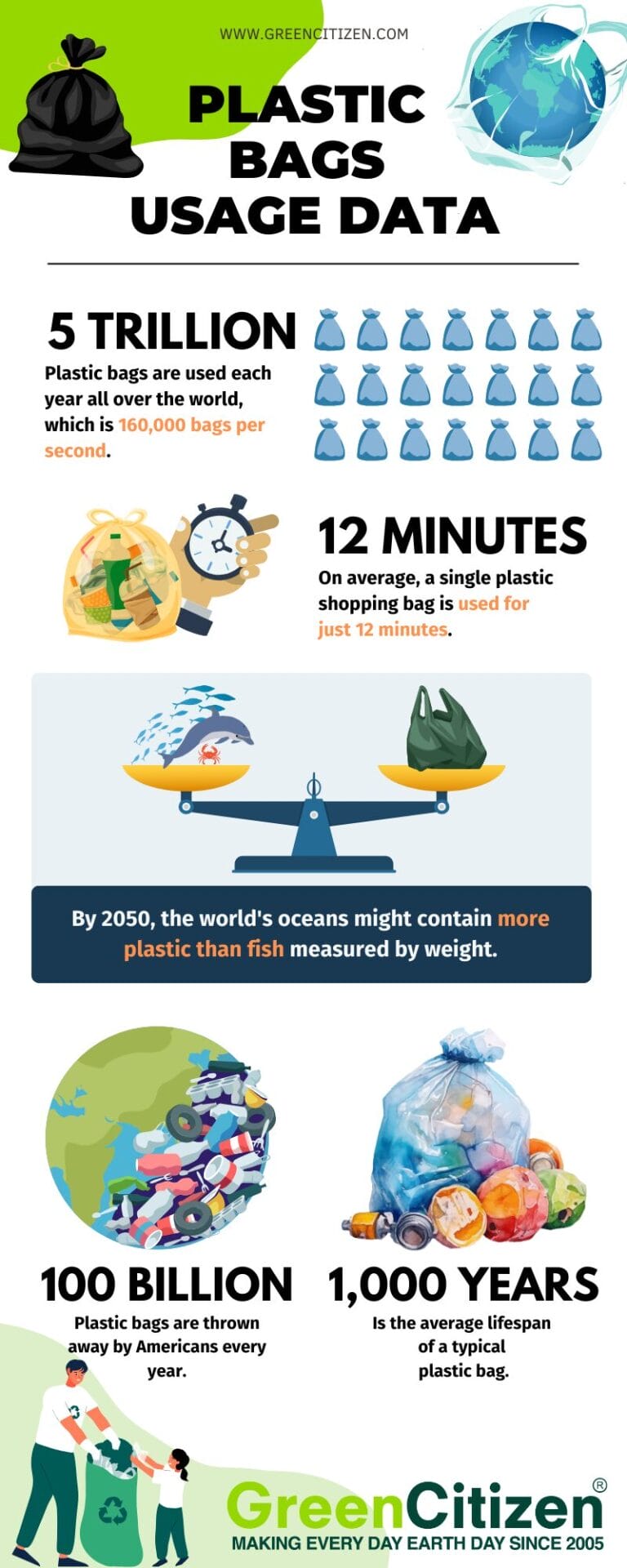

A significant amount of unrecycled plastic makes its way into oceans each year, with estimates ranging from 8 to 12 million metric tons annually.

Plastic waste enters marine environments through storm drains, rivers, and direct littering. Coastal areas with inadequate waste management systems are particularly vulnerable to plastic leakage into oceans.

Once in the ocean, plastics break down into microplastics, which are consumed by marine life and accumulate in the food chain. This bioaccumulation poses severe risks to marine ecosystems and human health, as toxins from plastics can be absorbed by seafood consumed by people.

Additionally, larger plastic debris, such as fishing nets and bags, entangles marine animals, causing injury or death. This not only disrupts aquatic ecosystems but also affects industries reliant on clean oceans, such as fishing and tourism.

Studies estimate that by 2050, there could be more plastic in the ocean by weight than fish if current trends persist.

The Global Shift in Plastic Waste Management

China’s National Sword Policy

In 2018, China implemented the National Sword Policy, banning the import of 24 types of solid waste, including most plastics. This decision sent shockwaves through the global recycling industry.

Until the policy’s enactment, China had been the world’s largest importer of recyclable materials, handling over 45% of the world’s plastic waste exports. Countries like the United States, the United Kingdom, and Japan relied heavily on China to process their plastic waste, shipping millions of tons annually.

The ban was introduced due to the high levels of contamination in imported recyclables, which rendered much of the waste non-recyclable.

Contaminants like food residue, mixed plastics, and hazardous materials increased processing costs and environmental damage. China’s move forced exporting countries to rethink their recycling strategies, highlighting the inefficiencies and unsustainability of shipping waste abroad.

Other Countries Following Suit

Following China’s example, countries like Malaysia, Thailand, Vietnam, and India began imposing restrictions or bans on plastic waste imports.

Malaysia, for instance, announced in 2019 that it would return 150 shipping containers of contaminated plastic waste to their countries of origin. But sadly, the Malaysian authorities are struggling to stop plastic waste imports.

Similarly, Thailand set a goal to completely ban plastic waste imports by 2025, citing environmental and health concerns.

These restrictions exposed the vulnerabilities in global waste management systems. Wealthier nations had relied on exporting waste instead of building robust domestic recycling infrastructures. As a result, plastic waste began to pile up in exporting countries, creating an urgent need for new solutions.

New Opportunities and Emerging Markets

The shift away from exporting plastic waste has prompted the development of local recycling infrastructure in many countries.

For example, the European Union introduced policies encouraging a circular economy, where products and materials are reused and recycled within the region. Investments in advanced recycling technologies, such as chemical recycling, are also gaining momentum. Chemical recycling breaks down plastics into their basic components, allowing them to be reused in manufacturing.

Governments and private companies are collaborating to address the issue. In the U.S., states like California have introduced stricter recycling regulations and invested in recycling facilities.

Private companies like TerraCycle and Loop Industries are innovating to create closed-loop systems, ensuring plastics are recycled efficiently and sustainably.

Meanwhile, developing nations are also investing in waste management systems, with countries like Indonesia committing to reduce ocean plastic waste by 70% by 2025.

These efforts indicate a growing recognition of the importance of managing plastic waste responsibly. While challenges remain, the global shift away from plastic waste exports is driving innovation and systemic change in waste management practices.

Is Recycling Plastic Enough?

Plastic recycling, often touted as the ultimate solution to waste, has limitations that prevent it from solving the plastic pollution crisis.

For one, the recycling process is highly dependent on proper sorting, which is far from foolproof. Contamination from food residue, mixed materials, or non-recyclable plastics often renders entire batches of recyclables unusable.

For example, a single greasy pizza box in a recycling bin can compromise an entire load of paper recyclables.

Additionally, many types of plastics can only be recycled a limited number of times before their quality degrades, a process known as downcycling. Unlike metals, which can be recycled indefinitely without losing their properties, plastics deteriorate with each cycle, eventually becoming unsuitable for further use. This means that recycling delays waste rather than eliminating it.

Economic viability is another barrier.

The cost of collecting, sorting, and processing plastic often exceeds the market value of recycled materials, especially when oil prices are low. Virgin plastic, made directly from petroleum, is often cheaper to produce than recycled plastic, discouraging companies from investing in recycled alternatives.

For instance, in 2020, the plummeting price of oil led to a decline in demand for recycled plastics, further undermining the recycling industry.

The Importance of Source Reduction

Given these limitations, many experts argue that the focus should shift from recycling to reducing plastic use altogether. Source reduction involves measures like banning single-use plastics, promoting reusable products, and encouraging consumers to opt for alternatives to plastic.

Policies such as the European Union’s Single-Use Plastics Directive, which bans items like plastic straws and cutlery, aim to curb plastic production at its source.

Encouraging a culture of reuse is equally critical. Refillable water bottles, grocery bags, and food containers can significantly reduce the demand for disposable plastics. Public awareness campaigns and incentives for adopting sustainable practices can help shift consumer behavior.

For example, some grocery stores now offer discounts to customers who bring their own bags or containers, reducing the reliance on plastic packaging.

The Role of Policy and Innovation

Policy interventions and technological innovations are crucial for addressing plastic pollution. Extended producer responsibility (EPR) is a policy approach that holds manufacturers accountable for the entire lifecycle of their products, including disposal. By shifting the financial and logistical burden of waste management to producers, EPR incentivizes companies to design products that are easier to recycle or reuse.

Research into biodegradable and compostable materials offers another avenue for reducing plastic waste. Innovations like bioplastics, made from renewable resources like cornstarch, can replace conventional plastics in many applications.

However, these materials are not without challenges, as they often require specific conditions for decomposition and may not be compatible with existing recycling systems.

The transition to a circular economy, where materials are reused and recycled indefinitely, represents a paradigm shift in how society manages resources. While recycling will always play a role in waste management, it is clear that it cannot alone solve the plastic pollution crisis.

A combination of source reduction, policy reform, and technological innovation is essential for creating a sustainable future.